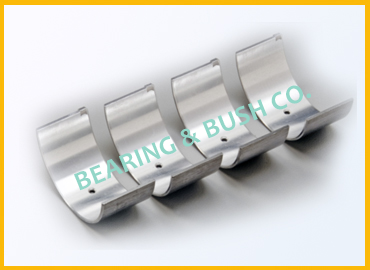

Half Shell Bearings

Our Products

We are a prime manufacturers and suppliers of half shell bearings categorized into steel backed tri metal and steel backed white metal parts offering best quality to our customers. These special purpose parts are precision engineered at our in house production facilities by our team of excellent engineers. For production of high quality metal parts it becomes essential to combine the raw materials, resources and the process in an effective way, by taking into account the industry standards ,so that seamless parts can be obtained which display the features of high tensile strength, corrosion resistance and dimensional accuracy.

Steel backed tri-metal :Steel backed tri metal is manufactured by using lead bronze with an overlay of nickel as a lining material. The main part used in the making of tri metal includes steel and a mixture of other alloys. The fusion of steel back and aluminum tin alloy is done by a centrifugal process.

Steel back supporting the bearing structure provides rigidity under severe conditions of temperature increase and rotating loads. The intermediate layer, usually an alloy has minimum anti-frictional properties, but, high fatigue strength to provide durability while working under alternating loads. Necessarily, the intermediate layer is applied on the steel back surface by the process of casting or sintering. This layer is composed of a calculated mixture of copper, lead and tin. Nickel is deposited between the intermediate layer and the overlay to prevent the movement of mixture from the overlay to the intermediate part. This is done because if both mixtures get combined it will be harmful for the corrosion resistant factor. The depositing of nickel is done with the process of electroplating.

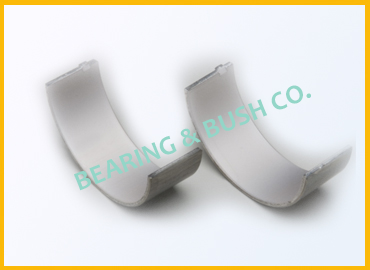

Steel backed white metal :White metal is an important category of metal used in various industrial applications. The product is highly corrosion resistant due to the tin content used in the manufacturing activities. White metals are non-ferrous metals which are soft, ductile but, tough. The co-efficient of friction exhibited by these metals is high and the wearing rate of this metal is low. These are used in making of jewelry, silvercoated ornaments bearings, electronic items and many other applications. White metal alloys are generally made up of metals such as antimony, tin, cadmium, bismuth and zinc. We cannot detect all of these metals in steel backed white materials, but a calculated proportion of these metals is mixed to get decided product. Chromium is considered to be the strongest white metal with a distinctive silvery color and it is frequently used with steel to create steel products.